Table of Contents

Over the many years during which we have prepared these special features for our readers, we have seldom chosen a self-unloader as our Ship of the Month. We can think of no particular reason why this should be so, except perhaps that true self-unloaders, as we now know them, are really products of the technological advances of the last sixty years; in contrast, many of the ships we have featured have been much older, or were operated by fleets which never ran self-unloaders of any description. In fact, checking back over our records, we find that the only true self-unloading bulk carriers (excluding sandsuckers) that we have described in detail have been the steamers OVERLAND, COLLIER, BAYANNA and BAYGEORGE.

With this issue, we will attempt to rectify the situation by presenting the story of the self-unloading canaller VALLEY CAMP. We have been intending to do so for quite a while now, having received several requests from members to feature her as a Ship of the Month. We are indeed pleased to do so, for VALLEY CAMP was really a Lake Ontario boat and members who reside near the Upper Lakes may never have had an opportunity to see her in operation. As well, she has been gone from the scene for more than a decade and a half, and some of our younger members may never even have heard of her.

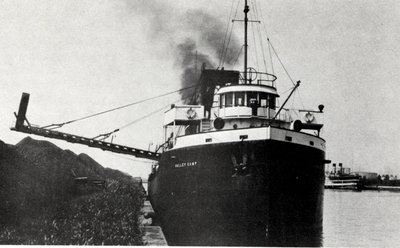

Photo by J. H. Bascom shows VALLEY CAMP unloading in the Toronto Ship Channel about 1934. The idle passenger steamer CORONA shows at right.

The Valley Camp Coal Company of Canada Ltd., an affiliate of the Oglebay Norton interests of the United States, was a major distributor of coal, particularly in the Toronto area. (Readers may recall that Valley Camp operated the coal bunkering facilities which were located at the far end of the West Street Wharf at Port Colborne.) Until Valley Camp decided to obtain a collier of its own, much of the company's coal was carried by vessels owned by James Playfair of Midland. In fact, there was a very close relationship between Playfair and Valley Camp for many years, although this association was eventually terminated.

Late in 1926, Valley Camp decided to have a coal carrier built for its own use, the new vessel to be operated by Playfair on behalf of the coal company. The order was placed with the famous British shipbuilding firm of Swan, Hunter and Wigham Richardson Ltd., which constructed the ship as Hull 1228 of its Neptune Works at Newcastle-on-Tyne, England. The steel hull was 252.3 feet in length (259.5 feet overall), 43.3 feet in the beam, and her depth was 23.6 feet. Her Gross Tonnage was 2351. while the Net Tonnage was registered as 1327. The steamer was powered by a triple expansion engine which was built by the C. & G. Cooper Company of Mount Vernon, Ohio. It had cylinders of 17, 25 and 43 inches, and a stroke of 30 inches, and developed Indicated Horsepower of 900. Steam at 180 p.s.i. was supplied by two coal-fired, single-ended Scotch boilers which measured 12'6" by 10'6".

The vessel was launched early in 1927 and was enrolled as BR. 149427. She was originally registered at Newcastle, as were many of the canallers built there for Canadian owners. The ship retained her British registry into the mid-1930s at least, although she was latterly transferred into Canadian registry as C.149427 (the Canadian and British registries used the same series of numbers at that time), with a "home port" of St. Catharines.

It has not been unusual for a lake vessel to be laid down under one name but commissioned under a completely different name, as a result of change of mind by the owners or an objection by the registry officials to the name first chosen. In fact, Valley Camp's new steamer went through two such name changes before she was officially enrolled. Playfair, being of Scottish decent, usually named his boats for places in Scotland, with the prefix 'GLEN' added even if the actual place did not carry such a prefix in its name. Accordingly, the new self-unloader, although not actually owned by James Play fair, was laid down as GLENKINLOCH. For some reason, perhaps because the Valley Camp Coal Company did not wish the name of the boat tied in so closely with the Playfair holdings, the name was changed to KINLOCH, and it was under this name that the ship was launched on February 1st, 1927.

It is a bit difficult at this late date to verify the origin of the name KINLOCH. The Highlands of Scotland are liberally endowed with places whose lengthy names begin with the prefix 'Kinloch'. It seems most likely, however, that the ship was named for Kinloch Castle, which is located at the head of an inlet from Cuillin Sound on the Isle of Rum in the Hebrides. Rum is a small island which is situate to the south and west of the lower end of the Isle of Skye, off the western shore of mainland Scotland.

It developed, however, that the name KINLOCH was not acceptable to the registry officials, probably because of the existence on the rolls of another vessel of the same name. As a result, the name KINLOCH was painted out and the steamer was officially christened VALLEY CAMP. She was to carry this name for all but two years of her career, which spanned four decades, but for many years the raised outline of the letters of the name KINLOCH could be seen under the paint on her bows, a mute reminder of the name under which the steamer had been launched into the waters of the River Tyne.

VALLEY CAMP was a typical canaller of the period, although she was rather more substantial in appearance and build, no doubt because of the need for extra strengthening to carry her self-unloading gear. She had a half-forecastle (raised a half-deck-level above the spar deck), and the forward crew was accommodated in what was called the "sunk forecastle deck" below. On the forecastle, which sported closed bulwarks for about half its length, was located the round-fronted texas cabin; it contained the master's bedroom and office as well as his private bath. The rounded pilothouse, which had seven large windows across its front, was placed on the bridge deck, and the raked foremast rose just abaft the pilothouse. Atop the pilothouse was a flying bridge, with a navigation platform (protected by canvas awning and dodger) together with wings extending out to the sides of the vessel.

The ship's stern was graced by an exceptionally shapely counter, of heavier lines than that given to most Canadian canallers. A substantial after cabin sat on the flush quarterdeck and provided accommodations for the engineroom staff as well as four deckhands, and also contained the galley and officers' and crew's messes. From this cabin sprouted VALLEY CAMP's tall, heavy stack, which was beautifully raked. The mainmast was stepped forward of the funnel.

VALLEY CAMP was given a simple unloading boom which was free from the lattice-work overhead bracing which was required to support the booms on larger vessels. It was hinged on the after end of the cargo elevating equipment, which rose at an angle from the deck, facing aft. The boom was suspended from a structure which was not really an A-frame but rather something more closely resembling a gallows-frame, and which had two braces running from its top downward and outward, one to each side of the deck just abaft Number Two Hatch.

Because of her unloading equipment, VALLEY CAMP was given a rather unusual hatch arrangement. Numbers One and Two were relatively narrow, positioned between the deck winches abaft the break of the forecastle. Numbers Three, Four, Five and Six were not single hatches but rather pairs of small openings situate under and down either side of the boom-frame and elevator. Numbers Seven through Twelve were of full width, running down the deck under the boom. Number Thirteen was a narrow hatch, located just forward of the after cabin and between the two aft mooring winches. The unloading boom reached down the deck to the midpoint of this hatch and, when at rest, was secured to horses mounted on the deck between Hatches Eleven and Twelve. The bunker hatch was located abaft the stack, with the coal chute running down through the cabin just forward of the engineroom skylight. All of the hatches were, in typical canaller fashion, covered only with sectional wooden covers, which had to be manhandled into place, dogged, and protected from the seas and the elements with canvas battens.

VALLEY CAMP had three cargo holds, separated by bulkheads. Number One hold ran to just abaft Hatch Five, while Number Two extended back to just abaft Hatch Nine. The holds were of unusual arrangement due to the unloading gear. VALLEY CAMP had steam-powered equipment with two scrapers. The British had never seen such an arrangement before, for VALLEY CAMP was the first such boat built for Canadian trade, and self-unloaders were a peculiarity of the Great Lakes at that time. The first self-unloading canaller built in Britain was COLLIER, which came out in 1924, but she had unloading equipment of a completely different type.

Scraper-type self-unloaders were once very common on the lakes but now they have become very much a thing of the past, their primitive machinery far outclassed by the conveyor dumping systems, loop-belt elevators, etc., that are now so much a part of the modern self-unloading bulk carrier. We can think of no better way to depict the construction and workings of a scraper-type boat than to quote the description of VALLEY CAMP which appeared in the June 10, 1927, issue of the British magazine, "Engineering".

"The self-unloading gear is the great feature of VALLEY CAMP's interest. This was designed and supplied by the inventor, Mr. Leatham D. Smith of Sturgeon Bay, Wisconsin. The vessel is divided into three holds, each having a large number of hatchways to facilitate rapid loading. The bulkheads are pierced at the bottom by a pair of longitudinal tunnels inside which the scrapers move, and by a third smaller one between them housing the back-haul scraper ropes. All three have sloping roofs with a central ridge, and the bottom of the holds are also made with a slope.

"The tunnels extend the full length of the holds and communicate with all of them by openings which are controlled by sliding doors, except in the afterhold where none are needed. On opening the doors of any particular hold, the cargo gravitates down the sloping floors of the holds and through the apertures into the tunnels. Here it is caught by the travelling crescent-shaped scraper and dragged forward along the smooth steel floor of the tunnel. At the forward end of the tunnel, the floor slopes up to the top of a hopper into which the load entrained in the scraper is discharged. The motion of the scraper is then reversed, and it is returned in such a manner as not to disturb the fresh supply of cargo that has accumulated during its forward journey.

"The contents of the hopper are delivered onto a conveyor belt 48 in. in width, running to a point above the main deck through a tunnel in the upper part of the forward hold. This belt discharges directly onto another of the same width carried on the swinging boom. The boom has a length of 85 feet and is capable of discharging at a maximum distance of 62 feet from the ship's side at a height of 30 feet above the level of the deck. The maximum inclination for both conveyor belts is 22 degrees to the horizontal. The discharging capacity of the apparatus is 600 tons per hour.

"Considering the unloading plant as a whole, the question of the suitability of a belt conveyor in the tunnels may arise. From the point of view of seaworthiness, the scraper has the great advantage of not interfering with the fitting of watertight doors in the tunnels at the bulkheads, as required by the regulations of Lloyd's Registry and British Corporation. The tunnels themselves are simpler in construction and are not so large. From this latter follows a saving of space, the cargo capacity of a ship fitted with tunnel scrapers being about 15 per cent. greater than that of one fitted with tunnel conveyors, while in a vessel of the size under consideration the centre of gravity is lowered by about two feet, thus increasing the stability.

"The flow of the cargo to the scraper is of the nature of an underfeed, and not an overfeed as with a belt conveyor, and both the first cost and maintenance expenses are lowered due to the employment of fewer and simpler working parts. Breakage, when the cargo is coal, is reduced to a minimum, and very sluggish materials such as fine wet coal, wet sand, or ore can be handled effectively; the same materials in a conveyor plant require much more handwork to get them through the hold hopper bottoms. The short space required by the incline to the scraper discharge hopper as compared with a conveyor incline makes it possible for a trimming tank to be fitted in the bow. The ship is corrected for list when unloading by means of ballast tanks in the wings and double bottom.

"The scraper is of the Sauerman type and consists of a crescentric bucket without top or bottom and having the sides formed of approximately conical surfaces with the bases of the cones opposed. The bottom edge is provided with an adjustable wearing blade. The scraper is strengthened across the mouth at the top by an arch of angles and plates, while lower down is the point of attachment for the dragging yoke of chain. The end of the back-haul cable is attached to a small trolley running on an I-section joist at the top of the tunnel. The cable, after passing over a pulley fixed to the back of the scraper, is returned over a pulley carried on the trolley and is thence led aft to guide pulleys on the forward boiler room bulkhead.

"From this point, it is taken along the central tunnel to the hauling engine which is situated forward under the scraper incline leading to the hopper. When the scraper is loaded, dragged along with a charge of material enclosed in it, its weight causes it to lie with the whole lower edge on the floor, and the trolley runs some distance behind it, depending on the precise tension of the ropes. At the beginning of the return journey along the level, when the back-haul cable is tightened, the back of the scraper is drawn up to the trolley before the latter begins to move along the runway, and so any fresh material which has accumulated during the forward journey is not swept back along the tunnel. The hauling and back-haul cables, of steel wire, are wound on separate drums of the hauling engine. Each drum is controlled by an independent lever so that the proper tension may be maintained on the cables Any communication between the attendants of these engines and those driving the conveyor belts is made by signal lights as in railway practice...

"The drives for both conveyors are situate above deck, that on the boom conveyor being at the tail pulley, and that on the fixed conveyor at the head pulley. Each has a single-cylinder horizontal (steam) engine connected to the pulley shaft by gearing. The somewhat peculiar arrangement of the pipes adopted is due to the necessity for slewing the unloading boom as well as tilting it, the steam pipe coming from a swivel joint on top of the chute, while another, near the governor, allows movement in a vertical plane.

"The structure of the boom-hoisting tripod will be clear. Stability athwartships is ensured by splaying the forward legs to the sides of the ship, an arrangement permitting the considerable forward range of the boom. The boom is slewed by a 6" by 6" winch, situated on the port bow (just behind Number One Hatch). The cable is led across the deck to the starboard side for slewing in the opposite direction, and the winch is fitted with two drums on the one shaft so that winding in and paying out synchronise, and the boom is thus held in position."

Considering the fact that VALLEY CAMP was the first self-unloader of this type built in Great Britain, and one of only a handful then operating even on the lakes, it is not surprising that she was given an exhaustive series of trials before delivery, these tests including the actual unloading of car go in addition to the usual engine exercises. VALLEY CAMP passed her trials with flying colours and, on April 28, 1927, sailed from Newcastle for Canada with a cargo of Marley Hill patent coke. The cargo was destined for the Chicago area, where VALLEY CAMP safely delivered it. The coke cargo was an experiment, for coke had never before been handled in a boat with scraper-type gear, and it was hoped that the equipment would be able to deal with the car go with a minimum of breakage of the coke. We have been unable to locate reports confirming the results of the maiden voyage experiment, but must assume that builders and owners alike were satisfied with her performance.

VALLEY CAMP went into regular service during the summer of 1927, carrying assorted cargoes but mainly coal for her owner. As she was operated by James Playfair, she carried the usual Playfair colours, a grey hull, white forecastle rail and cabins, and a red stack with a black top. She was a very impressive ship, especially with the closed rails on her flying bridge.

Within a few years, however, the open bridge was removed from the monkey's island, complete with its wings. A rail was left around the top of the pilothouse, but even that eventually disappeared. The supports for the boom frame were altered, with the splayed legs being replaced by guy cables. As well, the Valley Camp Coal Company took over the operation of its steamer from Playfair after but a few years of service. The company then adopted its own livery for VALLEY CAMP; her hull became black, the cabins and forecastle rail remained white, although the after cabin was given a dark red band up to the door sills. The stack became black with a red diamond edged in white, with the intertwined letters 'V.C.' in white on the diamond.

VALLEY CAMP operated only sporadically during the years of the Great Depression, emerging from lay-up every once in a while to bring a load of coal from Oswego to Toronto. These trips were sometimes made on such an impromptu basis that, on several such excursions, she was observed to be running with her lifeboats still wrapped in lay-up condition. Once business conditions improved again, however, VALLEY CAMP returned to full service, a state that she was able to enjoy right through to the end of her days.

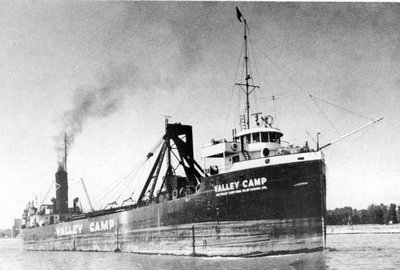

During the 1940s, VALLEY CAMP had her name printed in much larger letters on her bow, with the company's name added prominently just beneath. During the winter of 1950-51. her name was also painted in large white block letters down her sides. These touches gave her a rather elegant appearance, especially considering the fact that she was always kept in immaculate condition, despite the dust and dirt generated by her coal cargoes. Also altering her appearance during the 1940s was the expansion of her pilothouse by the moving back of its rear wall by the width of one window abaft the doors, and the fitting of a "doghouse" for additional crew quarters. This new cabin was placed at the extreme after end of the boat deck.

VALLEY CAMP, fortunately, enjoyed a successful career that, considering the vigour with which she was used in the coal trade, was remarkably free from accidents. We are not aware of any strandings or collisions in which she might have been involved. In fact, we know of only one untoward incident of any nature, and that occurred during September, 1950. VALLEY CAMP was out on Lake Ontario when she managed to fracture her tailshaft, with the result that she lost her propeller. Helpless, the steamer called for assistance, and the Toronto Dry Dock tugs H. J. DIXON and H.J.D. NO. 1 went out and fetched VALLEY CAMP into the shelter of Toronto Harbour. Light ship at the time, she was towed down into the Ship Channel for repairs.

During 1950, the Valley Camp Coal Company had decided that VALLEY CAMP required lengthening in order to increase her cargo capacity. As a result, she was laid up at Port Weller for the winter of 1950-51, and there was given an additional midbody so that she now had four compartments and her length was increased to 304.2 feet. The reconstruction increased her tonnage to 2878 Gross and 2012 Net. Her unloading boom was at first left at its original length, but soon it also was fitted with a new section so that it was 138 feet long and again stretched all the way down the deck to about the midpoint of the last hatch.

After her lengthening, VALLEY CAMP saw only two minor alterations during her remaining years. During the winter of 1955-56, the support cables on her boom frame were removed and were replaced with two splayed legs on either side in order to provide additional strength. Over the winter of 1961-62, she was given a new smokestack, but the new funnel was an exact duplicate of the old one and the change resulted in no appreciable alteration of VALLEY CAMP's appearance.

It is the summer of 1962 and VALLEY CAMP is outbound in the Toronto Eastern Gap, likely heading to Oswego for another coal cargo. Photo by the Editor.

During most of her years of service for the coal company, VALLEY CAMP hauled coal out of Oswego, New York, to Toronto and Hamilton, as well as down down into the St. Lawrence River to ports such as Prescott. As a youngster, your Editor spent many happy hours on the inner west pier of Toronto's Eastern Gap, watching VALLEY CAMP unload at her owner's wharf located behind the inner east pier. She frequently rolled out dense clouds of black smoke, particularly when her scrapers were pulling forward with a heavy load. If the timing was right, we would be rewarded with the sight of VALLEY CAMP backing out of the slip and heading out the gap into the lake, perhaps with the afternoon sun glinting on her so that a good photo could be obtained.

But as time passed, the amount of coal being shipped from Oswego declined and most of the coal moving to Canadian lower lake ports came from the south shore of Lake Erie. To VALLEY CAMP fell the distinction of carrying the last load of coal out of Oswego. She loaded some 3,600 net tons of soft coal at the Erie-Lackawanna Railroad dock on December 7, 1963, and duly delivered the cargo to Hamilton. Never again would the smoke of a collier be seen heading across the lake or up to Hamilton with a load of Oswego coal.

With no more coal to move across Lake Ontario, the Valley Camp Coal Company had little business for VALLEY CAMP. Her coal trade was rapidly becoming a thing of the past, and the company, with only one boat, could not obtain or even partially fulfill any of the contracts for coaling the big Ontario Hydro generating plants. VALLEY CAMP remained in service through the 1964 season but then was laid up in her usual spot on the west wall of the Welland Canal just above Lock Eight, at Port Colborne.

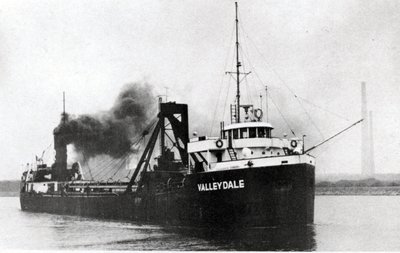

Early in 1965, VALLEY CAMP was sold to Reoch Transports Ltd., Montreal, and was renamed (b) VALLEYDALE. As she fitted out that spring, her old name was painted off her sides and her new name applied only on her bows. She was given the traditional Reoch stack colours, black with a broad red band and a large white letter 'R'. Looking not much different than she had in the colours of the Valley Camp Coal Company of Canada Ltd., VALLEYDALE operated for Reoch Transports through the 1965 and 1966 seasons. She carried almost any cargo that was available, but her days were numbered, for Reoch also operated a number of larger self-unloaders that had been acquired from the American Steamship Company of Buffalo.

The date is May 22, 1965, as VALLEYDALE heads out into Lake Erie from Port Colborne harbour. J. H. Bascom photo.

Accordingly, VALLEYDALE was sold for scrapping to United Metals Ltd. (United Steel and Refining Company) of Hamilton. She delivered herself to the scrapyard at Strathearne Terminals in the far eastern end of Hamilton harbour, arriving there under her own power on November 18, 1966. She lay in the mud at the scrapyard during the winter of 1966-67 along with the veteran steamer BROOKDALE (I), which also had been retired from the Reoch fleet, and the even older whaleback steamer JOHN ERICSSON, which had been retired in 1963 and had just come from a thoroughly unsuccessful interlude as a would-be marine museum in Hamilton's Confederation Park. VALLEYDALE was the first of the trio to be pulled up into the scrap bed, and there she was dismantled during the season of 1967.

And so came to an end the career of one of the most handsome canallers ever to sail the lakes. She was an interesting and well-maintained steamer and, despite the fact that she had been something of an experiment when built along the banks of the Tyne back in 1927, she had proven to be a very successful vessel. Indeed, it was really only her small size, even despite her 1951 lengthening, that brought her life to an end.

The British engineers had not been wrong when they extolled the virtues of VALLEY CAMP's unloading rig at the time of her completion, as strange as it may then have seemed to them. As things turned out, their only error was one of judgment in supposing that scraper-type unloading equipment was so much better than conveyors. Even so, it was not until many years later that technological advances permitted the development of the space and energy-saving tunnel and elevator conveyor systems that we know today.

Previous Next

Return to Home Port or Toronto Marine Historical Society's Scanner

Reproduced for the Web with the permission of the Toronto Marine Historical Society.